FCB Fabrication

FCB, FCPB are acronyms for Flexible Printed Circuit Boards. FCB's gained special attention because they solved the high density, electronically stabile, flexible, extremely thin, high thermal transfer and exceptional heat resistance that is necessary for the production of tight packaging. Products manufactured using FCB's allows the miniaturization, durability and weight to still provide the 3D adaptability for multichip modules. Flexible circuits have allowed some of the once impossible products and machines to become reality. With the ability to build specialized flex circuits that merge mechanical motion with electronic connectivity. The materials used to manufacture FCB's are what give it the ability to achieve extremely thin, dense and fatigue resistant results. Flexible circuit materials are halogen-free and by using these materials, flexible circuits are able to tolerate higher temperatures. FCB's also have extremely low moisture absorption. The materials used allow manufacturers to laser drill, punch, or chemically mill very small holes which gives room for more dynamic engineering possibilities. Products used to make FCB's include base films, conductor, finishes, masks, bondply, coverlays, conductors, adhesives and backers.

Flexible circuits represent many of the products we use today. They allow a simpler and more reliable solution then conventional pcb's. When it calls for tight packaging and coupled with maneuverability, you need a flexible circuits. Flexible circuits have allowed the products of tomorrow become a reality today. Below we have assembled general information on the materials and construction of an FCB.

Space

Flexible circuits generally can save you as much as 75% then conventional pcb, cables and terminations.

Weight

The inherently small design of the flexible circuit reduces the overall of weight of a product. Therefore saving a company money in many different aspects of the manufacturing process.

Assembly

Flexible circuits are not limited to one installation design. Because of their flexibility the packaging process can be changed many times without the redesign of another board or enclosure. Saving time and money in engineering and planning costs.

Absorption

Most flexible circuits are coated with a polyimide that resists the absorption of most chemicals and protects the fcb from harsh environments.

Reliability

Flexible circuits inherently with the materials and construction are able to withstand very long life spans while carrying a load during continual flexing. Consequently are much more reliable than a pcb in high vibration environments.

Single Layer

A single sided fcb has one conductive layer on a flexible, insulating, dielectric film that can either be made uncovered or with a coverlayer. A single sided fcb can have holes on one or both sides and may have components and stiffeners added depending the the nature of the design.

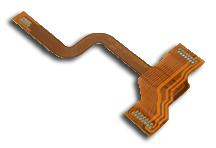

Double Layer

A double sided fcb has two conductive layers on a flexible, insulating, dielectric film that can either be made uncovered or with a coverlayer. Using a thru hole the layers are combined. Doubled sided layers often have fingers for assembly. A double sided fcb can have holes on one or both sides and may have components and stiffeners added depending the the nature of the design.

Multi Layer

A multi sided fcb has three or more conductive layers on a flexible, insulating, dielectric film that can either be made uncovered or with a coverlayer. Using a thru hole the layers are combined. Multi sided layers often have fingers for assembly. A multi sided fcb can have holes on one or both sides and may have components and stiffeners added depending the the nature of the design. Vias may be blind or buried. The use of multi sided fcb's may call for shielding depending on its application.

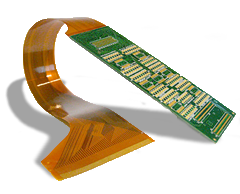

Rigid Flex

A rigid flex fcb is two or more conductive layers on a flexible and rigid, insulating, dielectric film that can either be made uncovered or with a coverlayer. Using a thru hole the layers are combined. A rigid flex fcb can have holes on one or both sides and may have components and stiffeners added depending the the nature of the design. Vias may be blind or buried. The use of a rigid flex fcb may call for shielding depending on its application.

Flex Coils

Flexible circuits can be made containing a flex coil. These coils are used for inductors and antennas. Flex coils can be arranged as a flat coil with fingers or leads, coils built inside the fcb, or coils that are on top of the fcb.

Coverlay

Flexible circuits use a material that is put on the external layers to insulate the board and its conductors. Polyimide and polyester are more common chemicals used to protect flexible circuits. Photoimagable/Soldermask are common on thin uses of copper and are applied using a photo process.

Shielding

Shielding is used when an the surrounding components require the protection from magnetic or static interference. Shielding is place on or around the conductive area or areas to control the interference. There are three types of common shielding, solid copper, crosshatched copper, and conductive silver.

Stiffeners

Stiffeners are used to support certain areas of an fcb that may require additional support from other components. FR4/G10, polyimide and polyester are the most common. The stiffener holes size should be larger than the thru hole for specific tolerances to be met. Stiffeners have many different thicknesses. Ranging from .010" to .062". Polyimide and polyester stiffeners are fastened using an adhesive, or a heat set adhesive.

Termination

There are a few ways to mate a flexible circuit to external devices. Crimped contacts, fingers, surface mount connectors and zero insertion force connectors. Each has its own place in the design of individual fcb's. Depending on the application one may suite better than the other. Fingers can be flexible and made to suite your requirements. Surface mount connectors or thru hole connectors are the most commonly used.

At Integrated Circuit Technologies we are here for our customers. We have assembled "General Information" as a resource for our customers on how Flexible Circuit Boards are manufactured. For detailed information on your specific project please give us a call.

Contact Us